Starting your transformation journey

STEP 1

Commercial Modelling

STEP 2

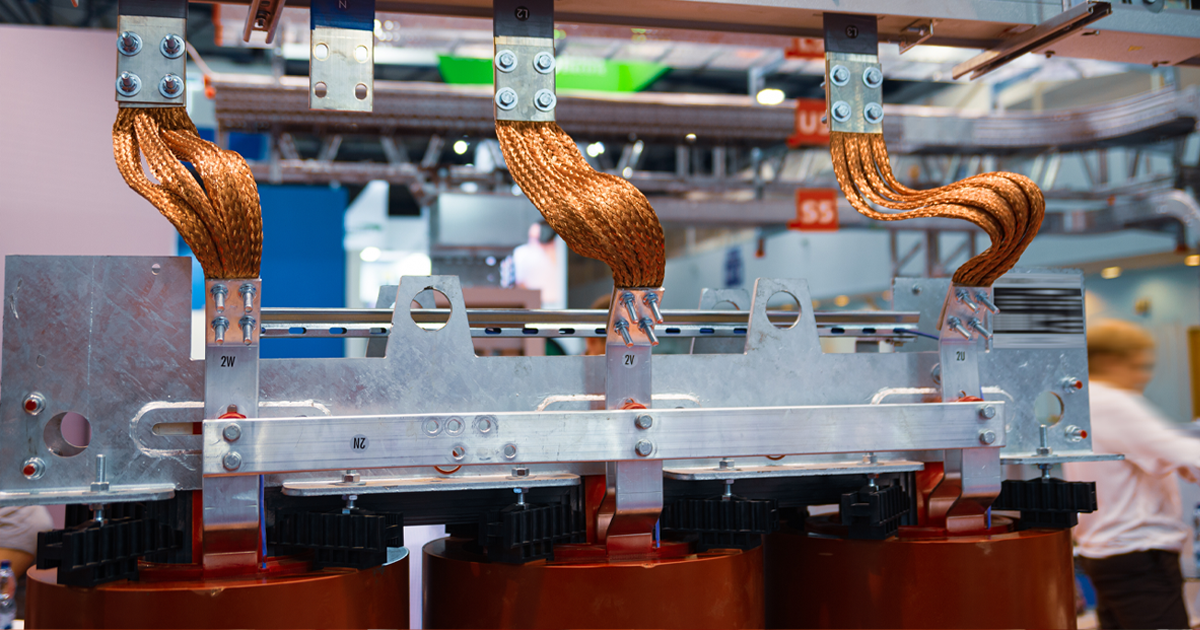

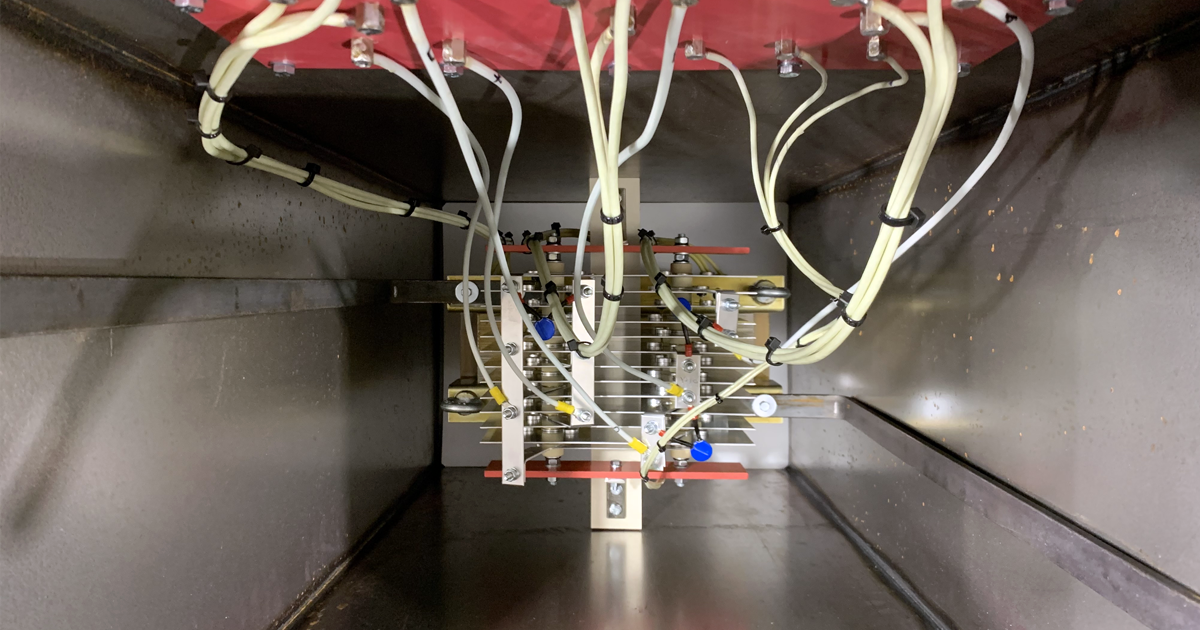

We delve into comprehensive technical modelling, employing a digital twin model to replicate the current and proposed infrastructure. This fundamental step ensures that our proposed solutions operate at peak technical efficiency, minimising risks to resilience and maximising potential benefits.

STEP 3

STEP 4

STEP 5

STEP 6

STEP 7

STEP 8

STEP 9

STEP 10

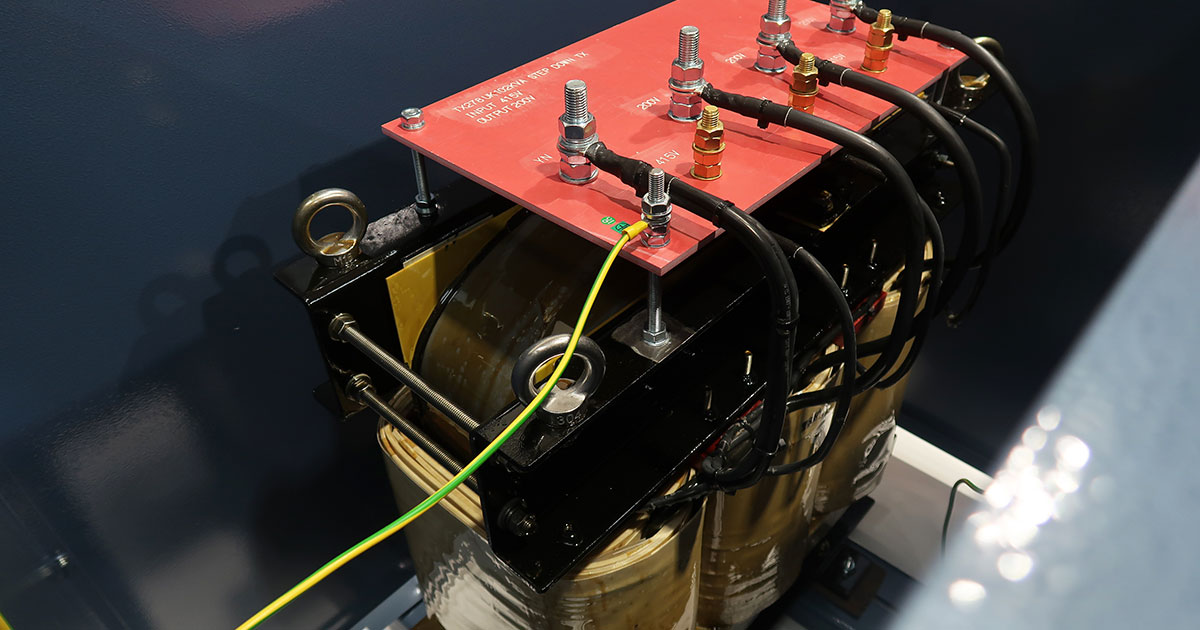

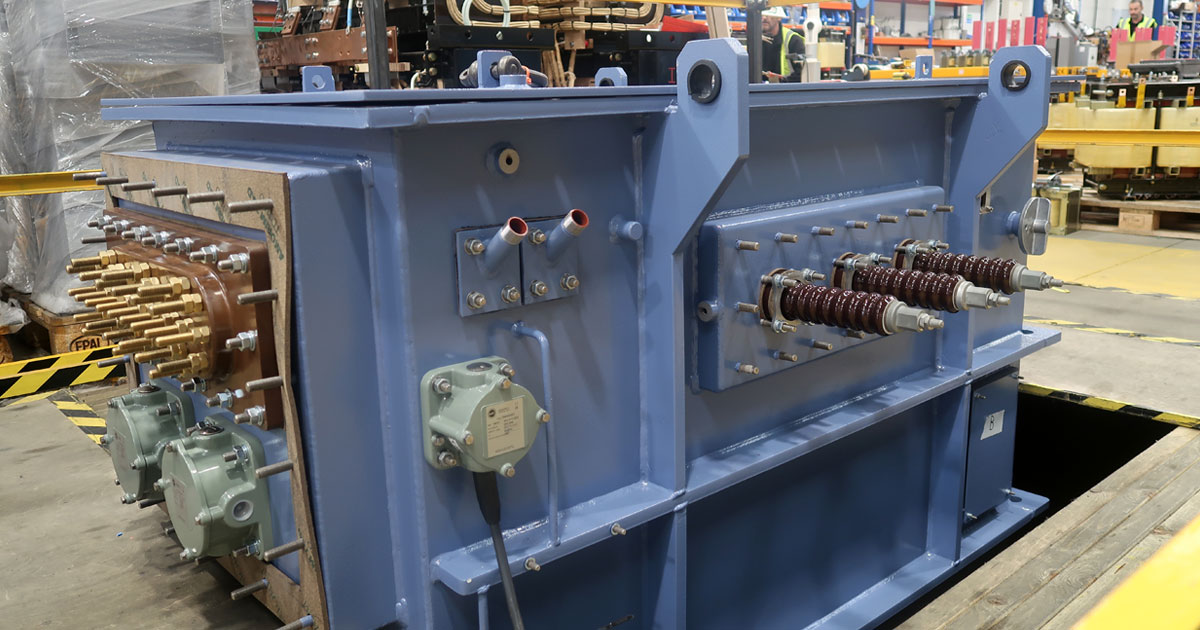

Our experienced Powerstar team takes charge of commissioning the asset and conducting the Site Acceptance Test (SAT). This meticulous process aims to minimise downtime risks while methodically recording all Beginning of Life metrics.

STEP 11

Our commitment extends beyond implementation. The dedicated 24/7 remote asset team ensures optimal system performance. Pre-emptive analytics are deployed to proactively prevent or shorten downtime periods. Annual performance reviews provide insights and recommendations for continuous improvement.

- Voltage Optimisation

- Become a Customer