Sector

Manufacturing

SOLUTION

Energy Efficiency

Power Resilience

Solving Grid Constraints

TECHNOLOGY

Battery Energy Storage

Voltage Optimisation

Challenge

Their manufacturing site in West Yorkshire had been suffering from increasingly frequent blackouts due to disruption to their grid supply. PSR relies on the continuous operation of its 7 on-site gas-fired kilns to fire its refractory products. Any disruption to the power supply will cause the kiln firing cycles to fail and have to be restarted once the product has cooled down, wasting valuable production time, energy and potentially damaged product This culminated in a run of six blackouts during a six-month period at huge cost to the business. Significant fluctuation in supply voltage presented an additional risk of disruption.

Parkinson-Spencer have made a clear commitment to building a sustainable manufacturing business and have already invested significantly in clean energy technologies. Therefore, any solution presented would need to directly support those efforts. The client was also looking for a product that would have a good investment return over the long term.

Solution

Powerstar and GridBeyond worked together to support Parkinson- Spencer objectives. Powerstar presented a combined technology solution that could protect the Holmfield site from blackouts and other power disruption, while also reducing energy costs and improving on the sustainability efforts already in place.

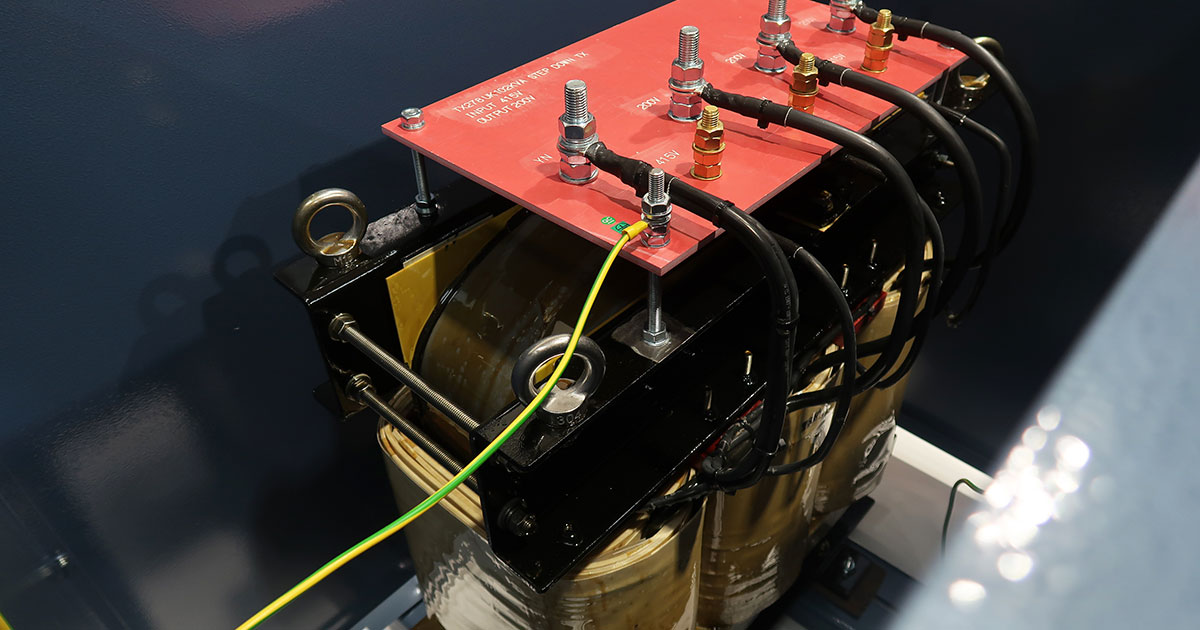

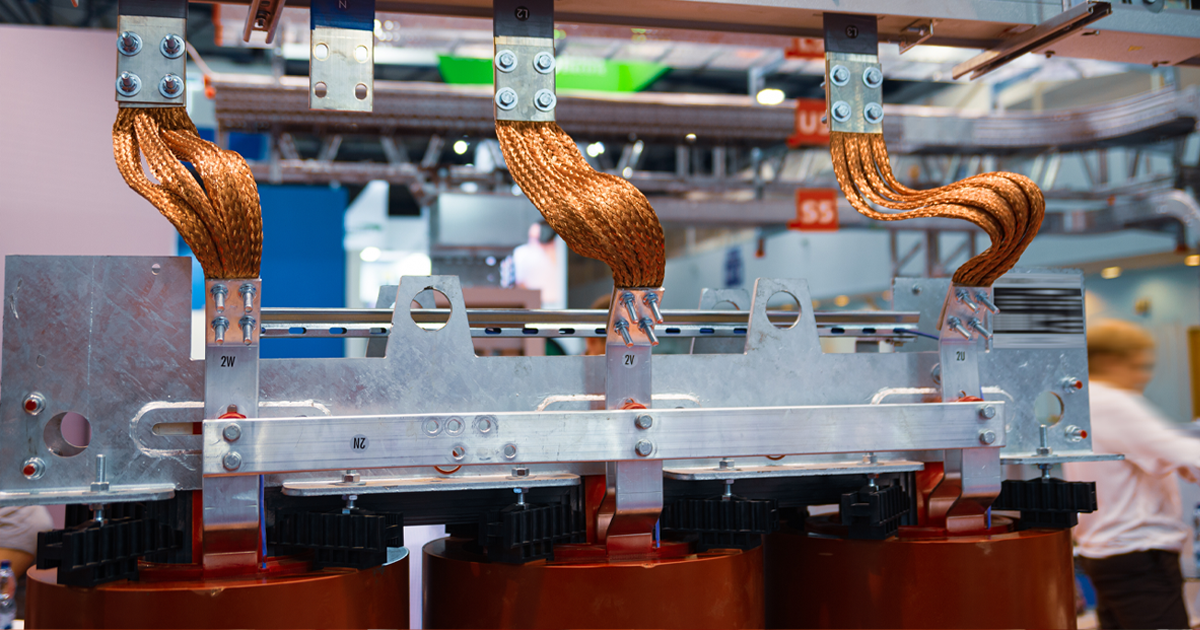

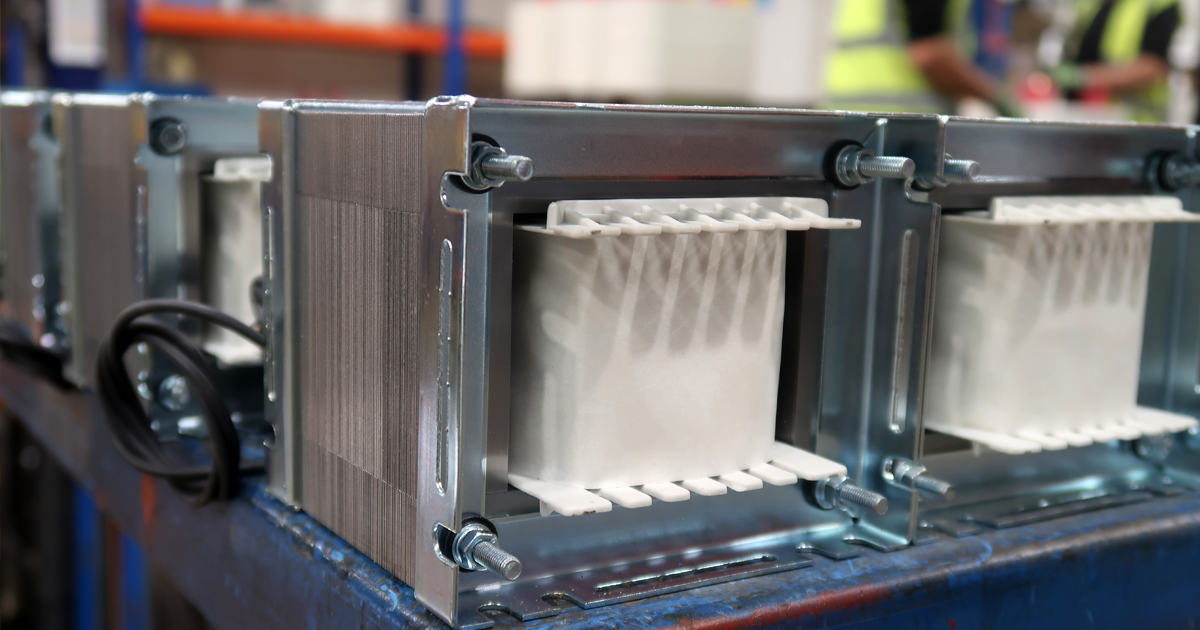

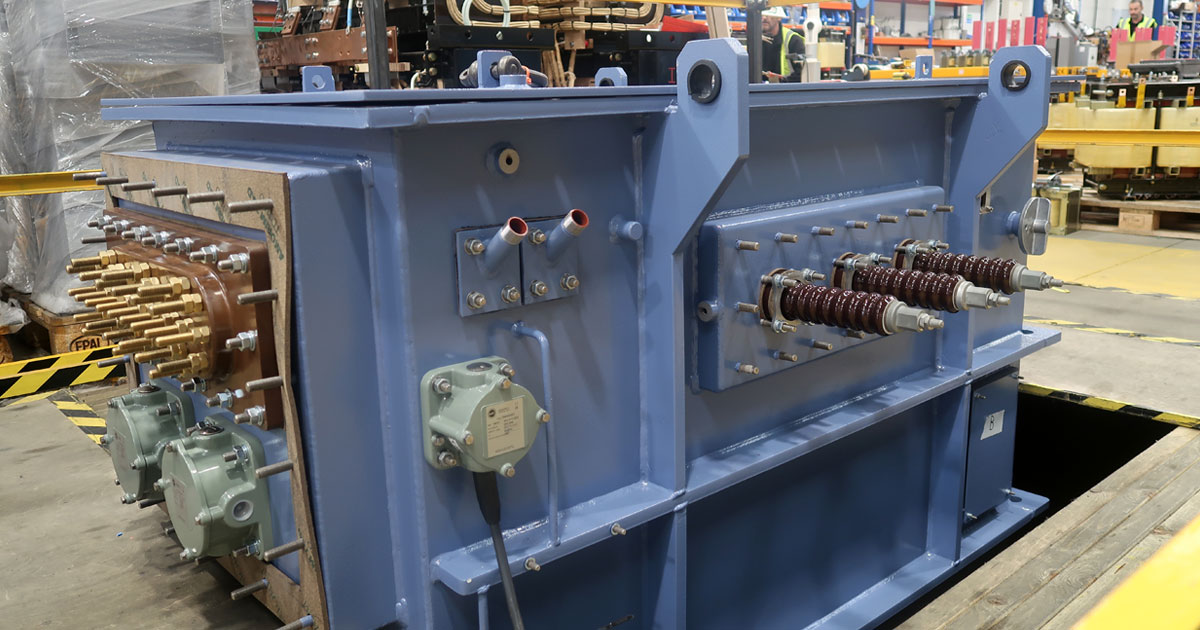

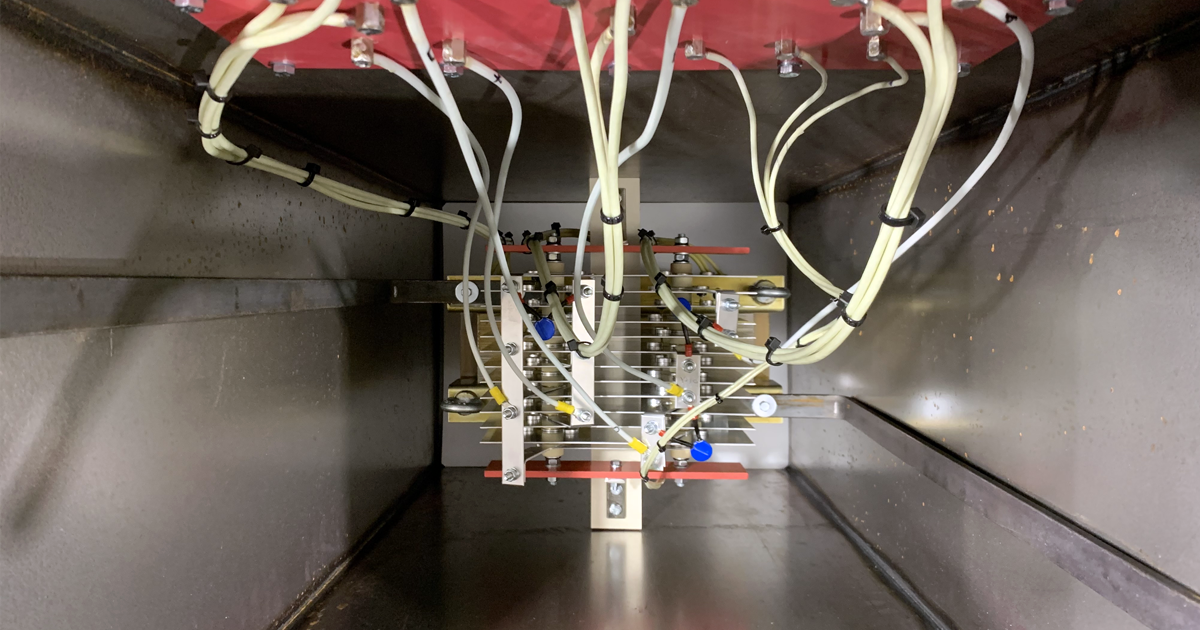

A 250kW battery energy storage system (BESS) was recommended after an extensive site survey, alongside a 500kVA MAX voltage optimisation system. Both systems were integrated into a single containerised solution on-site.

The Battery Energy Storage System (BESS) provides site-wide uninterruptible power supply (UPS), keeping the manufacturing process going in the event of a blackout. The flexible nature of battery energy storage also presented several additional benefits, including maximising the performance of the site’s on-site wind turbine generation and provided a new revenue stream by providing flexibility services to the National Grid. Voltage optimisation would provide a substantial reduction in energy consumption and subsequent costs and carbon footprint, while helping to improve the efficiency of on-site equipment

GridBeyond will be responsible for managing the flexibility of a 250kW on-site battery and enabling its participation in grid balancing services. By connecting the battery to the AI-powered energy technology platform, GridBeyond Point, energy flexibility of the hub will enable National Grid to integrate more renewable energy sources onto the electricity network. The optimisation of the grid will provide a substantial reduction in energy consumption and subsequent costs and carbon footprint.

In addition to advancing the Net-Zero agenda, Parkinson- Spencer will receive regular monthly revenue from National Grid for participation in frequency balancing services. GridBeyond’s platform will provide advanced energy monitoring, forecasting, and reporting on the battery and its state of charge, ensuring the flexibility is monetised through the most lucrative programmes and markets.

Result

The BESS from Powerstar will protect the site from any power disruption events that otherwise would halt the manufacturing process. Each blackout incident previously was estimated to cost the business between £20,000 and £100,000 in lost profits, materials, energy and labour costs, as well as the disruption to manufacturing schedules and potential reputational damage this could cause. Ongoing monitoring and maintenance of the system by Powerstar also ensures peace of mind that they can continue to produce their glass products and fulfil orders across the world without the risk of power disruption.

As well as further improving the sustainability of the site’s energy infrastructure, the project also delivers a guaranteed 5% reduction in energy costs through voltage optimisation, as well as additional revenue through grid balancing schemes, managed by GridBeyond. Given the significant cost to the business of blackouts previously, the system is expected to pay for itself within 2 years.

Protection From Power Disruptions

- Grid Constraints

With the ability to power our site for up to two hours the Battery Energy Storage System should cover us for all but the most severe and long-term power outages, thereby maintaining the operation of our critical kilns and protecting our products and production schedules. Given the damaging impact that interruptions to our power supply have caused for such a long time, and the added benefit of reducing our energy consumption and providing an additional revenue stream, the solution provided by Powerstar was a no brainer for our business.”

Simon Parkinson

Managing Director of Parkinson-Spencer Refractories Ltd

GridBeyond

GridBeyond have the expertise and ability to aggregate batteries around the country, so that sub 1MW batteries are able to enter the more lucrative new Dynamic frequency response markets, which require a 1MW minimum unit size per GSP.

As we grow our portfolio of sub 1MW battery systems, market access for new battery clients becomes easier.