Energy bills are one of the biggest costs for any business, and hidden inefficiencies in electricity use can quietly inflate expenses month after month. One factor that often goes unnoticed is voltage variation – when the electricity reaching your site fluctuates above or below the optimal level.

These fluctuations don’t just waste energy. Voltage that is too high or too low can reduce equipment efficiency, increase maintenance costs, and even shorten the lifespan of critical machinery. Voltage Optimisation (VO) tackles these issues head-on, helping businesses cut energy costs, boost operational efficiency, and protect valuable assets. In this blog, let’s break it down.

Why Voltage Varies

Electricity is delivered through a network of cables that connect homes, businesses, and factories to substations. Even though engineers try to minimise resistance in these cables, some voltage loss is inevitable. This means:

- Sites closer to a substation often receive higher voltage.

- Sites further downstream receive lower voltage.

- Voltage can fluctuate depending on overall demand at any given time.

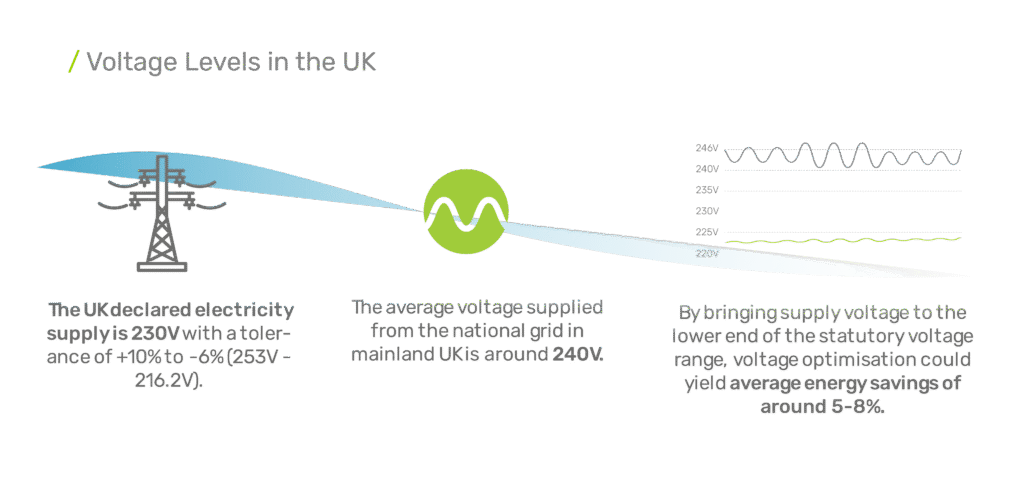

In the UK and Europe, the standard supply is 230V, but actual voltage supplied from the grid can vary between 216V and 253V. While equipment must function safely across this range, operating outside the ideal 230V can reduce efficiency and increase costs.

The Impact on Equipment

Many types of electrical equipment perform best at the nominal voltage. Induction motors, which account for around 75% of industrial electricity use, are a prime example. These motors generate a magnetic field that spins the rotor to produce mechanical power.

High voltage: When supplied with voltage above the nominal 230V, the magnetic field in the motor is stronger than necessary. This increases energy losses in the motor’s magnetic material, reducing overall efficiency.

Low voltage: When the supply is below nominal, the motor must work harder to maintain the same output. This increases current in the rotor, leading to higher resistive losses.

In both cases, the result is energy waste, higher electricity bills, and unnecessary stress on the motor. Over time, this can also increase maintenance requirements and shorten the lifespan of the equipment, adding further operating costs.

Variable Frequency Drives (VFDs)

Some motors are connected to Variable Frequency Drives (VFDs), which convert the incoming AC supply to DC and then back to AC with a controlled voltage and frequency. This allows motors to operate at a stable, optimal voltage, improving efficiency and reducing energy consumption.

However, VFDs themselves are sensitive to supply voltage variations:

- High voltage: Increases switching losses in the VFD’s electronics. These occur when transistors rapidly turn on and off to regulate voltage and frequency. Higher voltage magnifies these losses, reducing overall efficiency.

- Low voltage: Forces more current to flow through the VFD’s components, increasing conduction losses and generating additional heat.

- Long-term high voltage exposure: Can degrade key components such as electrolytic capacitors, shortening the VFD’s lifespan and leading to costly replacements.

By maintaining a stable nominal voltage, voltage optimisation systems reduce these inefficiencies in both motors and VFDs, lowering energy costs, protecting equipment, and supporting smoother, more reliable operations.

Broader Equipment Benefits

Voltage optimisation isn’t just for motors. Many types of industrial and electronic equipment operate most efficiently at 230V. When voltage is too high or too low, equipment can waste energy, perform inconsistently, or experience unnecessary wear.

This applies to a wide range of equipment, including pumps, fans, HVAC systems, electronic drives, lighting, and heating systems. By maintaining a stable, optimised voltage, businesses can improve efficiency, reduce energy waste, and extend the lifespan of their assets across the site.

Figure 2: Simplified schematic diagram of a typical Voltage Optimisation installation

Understanding Load Types

The efficiency benefits of voltage optimisation depend on the types of equipment, or loads, connected to your electrical distribution system. Loads can generally be classified as either voltage-dependent or voltage-independent:

Voltage-dependent loads are linear resistive loads where the power consumed changes with the square of the supply voltage. In other words, if the voltage increases, the energy these devices consume rises disproportionately, and if the voltage drops, their output decreases. Common examples include halogen lamps, fluorescent lighting with inductive ballasts, metal halide lamps, and some uncontrolled motors.

Voltage-independent loads are designed to maintain a fixed output regardless of supply voltage. Modern electronic devices, such as laptops, LED lighting, computer screens, and variable speed drive (VSD) controlled motors, fall into this category.

Many industrial and commercial systems are a mix of both types, for example: large VSD-controlled motors combined with smaller uncontrolled motors or pumps. Process loads and electric heating can also be dependent or independent, depending on how they are controlled.

| Load Type | Voltage Dependent? |

| Halogen lamp | Yes |

| Fluorescent lamp – inductive ballast | Yes |

| Metal halide / SON lamps | Yes |

| Fluorescent lamp – high-frequency electronic ballast | No |

| LED lights | No |

| Motor loads – uncontrolled | Often |

| Motor loads – variable speed drive controlled | No |

| Process loads | Depends on the control process |

| Electric heating | Depends on the controls – only if uncontrolled |

| Electronic loads (ICT) | No |

Understanding which loads are voltage dependent is important because voltage optimisation delivers the greatest energy savings on voltage-dependent equipment. Meanwhile, voltage-independent equipment still benefits from more stable operation, reduced stress, and extended lifespan.

Dynamic Voltage Optimisation vs Fixed

Voltage optimisation systems come in two main types: fixed and dynamic.

Fixed voltage optimisation reduces the supply to a set level and maintains it there. It’s simple, reliable, and provides predictable energy savings, but it cannot respond to fluctuations in supply or varying load conditions. Adjustments to the output can only be made when the system is electrically isolated, and while grid voltage fluctuations are mirrored in the output, the system provides a fixed percentage reduction in voltage. Fixed systems generally have the lowest CAPEX, but their energy savings are more limited and less flexible.

Dynamic voltage optimisation, on the other hand, continuously monitors the incoming voltage and adjusts in real time, maintaining the supply as close as possible to the ideal nominal voltage. It delivers a variable reduction in voltage, guarantees a minimum optimised voltage, and can be adjusted without interrupting the load. Grid voltage fluctuations are mirrored in the optimised output, ensuring maximum efficiency for all equipment. Dynamic systems typically have a higher upfront cost but provide greater energy savings and better protection for sensitive devices, especially in sites with varying demand or significant voltage fluctuations.

Figure 3: Representation of Dynamic and Fixed Voltage Optimisation

Business Benefits of Voltage Optimisation

Installing a voltage optimisation (VO) system can bring clear, measurable benefits:

- Reduce energy consumption and cut electricity bills by ensuring all equipment operates at its most efficient voltage.

- Lower maintenance costs and extend the lifespan of motors, drives, and other equipment, reducing unplanned downtime and replacement expenses.

- Reduce CO₂ emissions, helping your business meet sustainability targets and enhance its environmental credentials.

- Increase operational efficiency, ensuring machinery runs reliably at optimal performance.

- Protect sensitive equipment from voltage fluctuations, reducing the risk of damage and costly repairs.

- Support business resilience, as optimised voltage can improve process stability and reliability across your site.

In short, Voltage Optimisation is more than just an energy-saving measure – it’s a strategic investment that drives cost efficiency, operational reliability, and sustainability. By stabilising your electrical supply, you not only cut energy bills but also safeguard critical assets and future-proof your operations for long-term success.

Explore Powerstar® Voltage Optimisation – Cut Your Energy Consumption