Transforming energy efficiency: how Low-Loss Amorphous transformers can reduce your energy costs

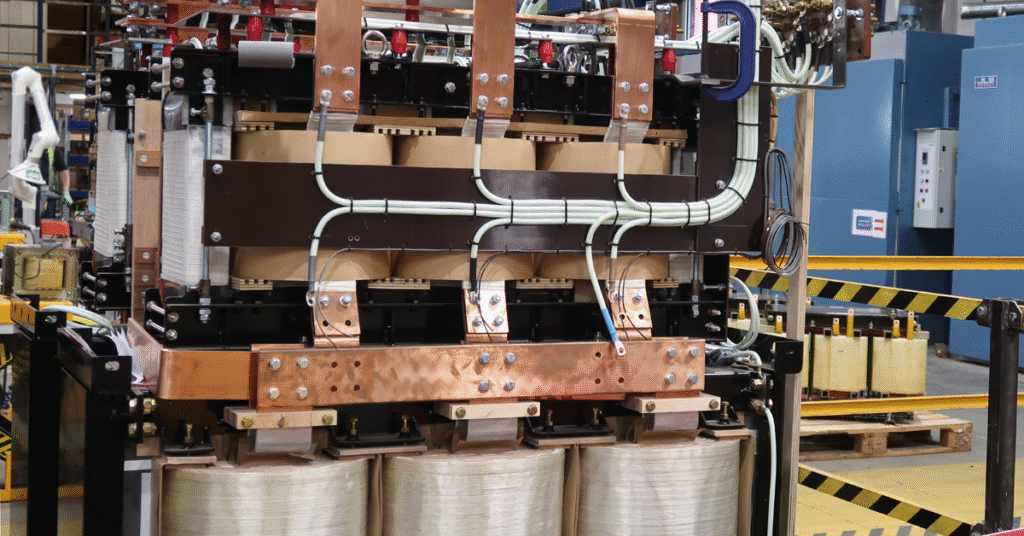

Transformers are the backbone of the UK’s power grid, delivering the stable, reliable power that businesses depend on every day. With rising energy costs, stricter carbon reduction targets, and the risk of disruptions to power supply, transformer efficiency is no longer optional – it’s essential for long-term resilience and sustainability.

For decades, transformer cores have been made from Cold Rolled Grain Oriented (CRGO) steel. While dependable, CRGO transformers are known to be far less efficient than modern alternatives, leading to higher running costs and unnecessary carbon emissions. And with the majority of UK transformers now over 20 years old, many businesses are operating with outdated transformers built with CRGO cores without realising the impact this has on resilience, efficiency and costs.

In recent years, there’s been a shift to modern amorphous core transformers, which offer higher efficiency and lower environmental impact. At Powerstar, we’ve seen organisations that upgrade to low-loss amorphous transformers achieve typical annual energy savings of around 3% per unit, alongside noticeable reductions in carbon emissions. In this blog, we explain why making the transition to amorphous cores isn’t just a smart decision – it’s an obvious one.

What are Amorphous Core transformers?

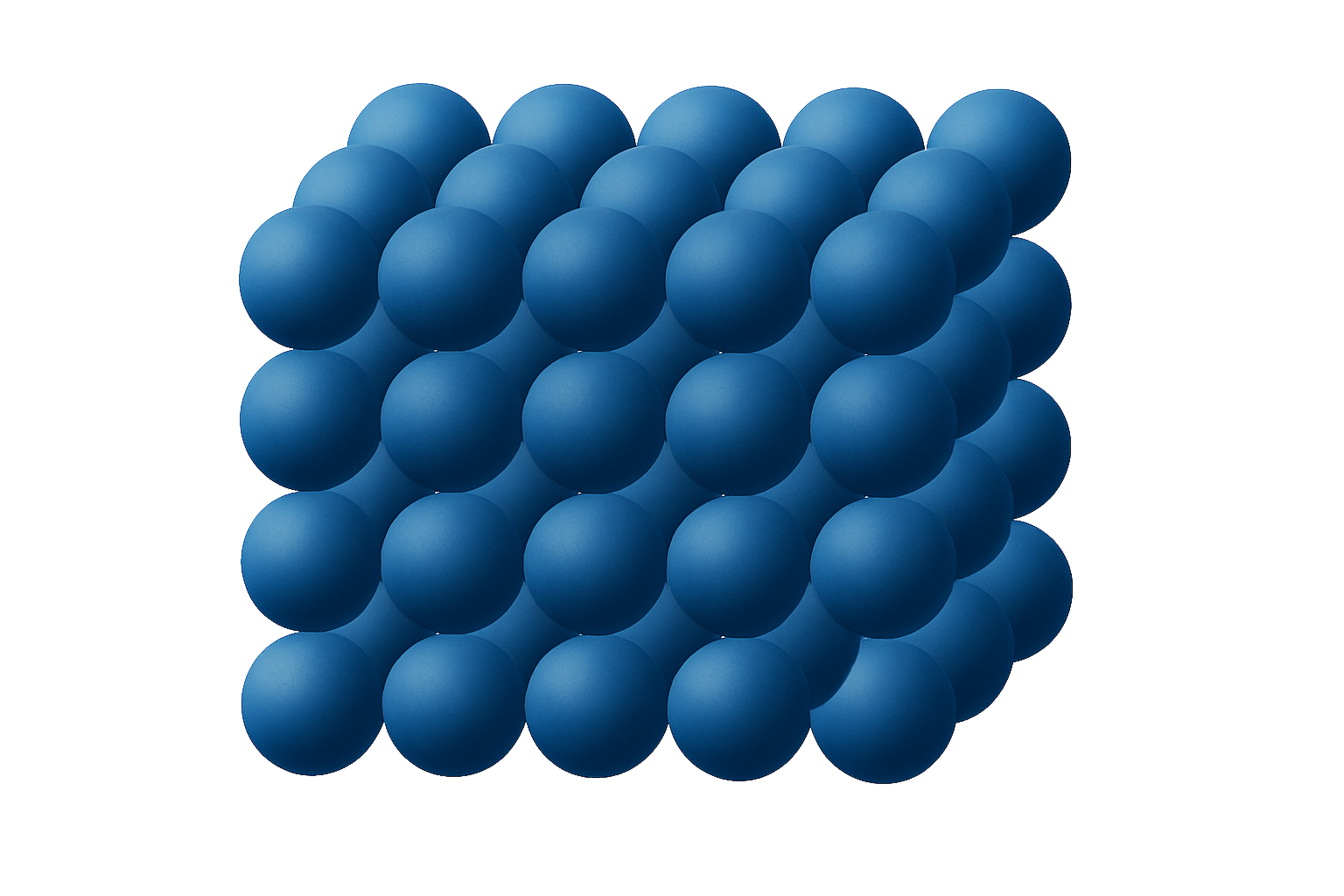

Traditional CRGO (Cold-Rolled Grain Oriented) steel cores have a carefully aligned crystal structure that allows magnetic energy to flow efficiently. This has made them a reliable choice for distribution and power transformers, as well as industrial motors. However, CRGO cores are prone to significant no-load losses, meaning they waste energy even when the transformer is energised but not supplying power.

Amorphous core transformers, on the other hand, use non-crystalline metal alloys, often referred to as “metallic glass.” Their unique atomic structure allows magnetic domains to shift more freely, reducing hysteresis losses and dramatically improving energy efficiency. This technology can achieve up to 70–80% reduction in no-load losses, helping businesses save on energy costs while reducing their carbon footprint.

Over time, these savings add up, making amorphous transformers a far more cost-effective and energy-efficient choice for businesses. And with today’s competitive pricing, amorphous cores are no longer the more expensive option they once were.

CRGO vs Amorphous: A side-by-side comparison

| Core Type |  CRGO (Cold-Rolled Grain-Oriented Steel) | Amorphous Steel |

| Atomic Structure | Crystalline, Orderly, Repeat | Non-Crystalline, Random arrangement |

| Core Losses (No-Load) | 100% – energy is wasted even when no load is applied | Up to 70–80% reduction in core losses |

| Available Form | Sheet, Roll | Thin Sheet, Ribbon |

| Saturation Flux Density | 2.03T | 1.56T |

| Lamination Factor | 96% | 86% |

| Efficiency | Moderate | Highly energy-efficient, especially under light loads |

| Heat Generation | High – can reduce transformer lifespan | Low – extends lifespan and reduces maintenance |

| Environmental Impact | Higher CO₂ emissions | Lower CO₂ emissions and energy footprint |

All sectors can gain from upgrading to amorphous core transformers, but some benefit more than others. Manufacturing, food & drink operations, utilities, and large commercial sites can often recoup their investment in three to five years, depending on energy usage and the efficiency of existing transformers.

Amorphous cores are particularly effective for equipment and systems that run continuously, draw consistent power, or are sensitive to voltage fluctuations. Key examples include:

Industrial Machinery: Large motors, pumps, compressors, CNC machines, and other heavy equipment with long operating hours benefit from reduced no-load losses and stable voltage, improving efficiency and reliability

Commercial and Public Buildings & Facilities: HVAC systems, lighting, elevators, and office equipment in large buildings or campuses run many hours daily. Lower transformer losses translate into substantial energy and cost savings and improved sustainability to better-meet ESG targets.

Food & Beverage Manufacturing: Continuous-process machinery such as ovens, conveyors, chillers, and bottling/filling lines operate around the clock, making transformer efficiency critical for reducing costs and carbon emissions.

Renewable Energy & Storage Systems: Solar inverters, wind turbines, and battery energy storage systems benefit from low-loss transformers that maximise efficiency and minimise energy waste.

What about costs?

When amorphous core transformers were first introduced, their upfront cost was noticeably higher than conventional CRGO units. While CRGO transformers may have seemed better value initially, they quickly cost money through their inefficiency.

In high-load, continuous operating settings, conventional transformers can waste around 2-5% of energy. This wasted electricity adds up quickly, costing as much as the transformer’s purchase price in less than a year.

Amorphous core transformers, by contrast, waste less than 1% of energy and emit 70-80% less CO₂ emissions, making them an ideal choice for sustainability-conscious businesses. By delivering consistent savings year after year, they generate a far higher return on investment. Recent supply issues have also pushed up CRGO steel prices, narrowing the cost gap between the two core types. With CRGO costs rising steadily, upgrading to amorphous core transformers has never made more financial sense.

Powerstar’s approach

At Powerstar, our amorphous core transformers are custom-designed to maximise efficiency for your specific operational requirements. We combine advanced materials with expert engineering, delivering solutions that:

- Lower operational costs and energy usage

- Improve transformer lifespan and reliability

- Support compliance with energy efficiency standards

Whether you’re upgrading ageing transformers or planning a new installation, Powerstar can design, supply, and commission solutions that future-proof your energy infrastructure. Find more about our low-loss transformers here.

Transitioning from CRGO steel to amorphous core technology is more than a technical upgrade – it’s a strategic business decision. By significantly reducing no-load losses, amorphous core transformers can deliver substantial energy savings, lower carbon emissions, and improve reliability. While the exact benefits depend on transformer size, load, and operating conditions, upgrading to amorphous cores is one of the smartest investments a UK business can make in 2025 and beyond.

Powerstar is ready to help your business make the switch. Contact us for a bespoke consultation to explore how upgrading to low-loss transformers can reduce energy costs, lower emissions, and enhance operational resilience.