Sector

Manufacturing

Critical Process Manufacturing

SOLUTION

Energy Efficiency

Net Zero

Reducing Energy Costs

TECHNOLOGY

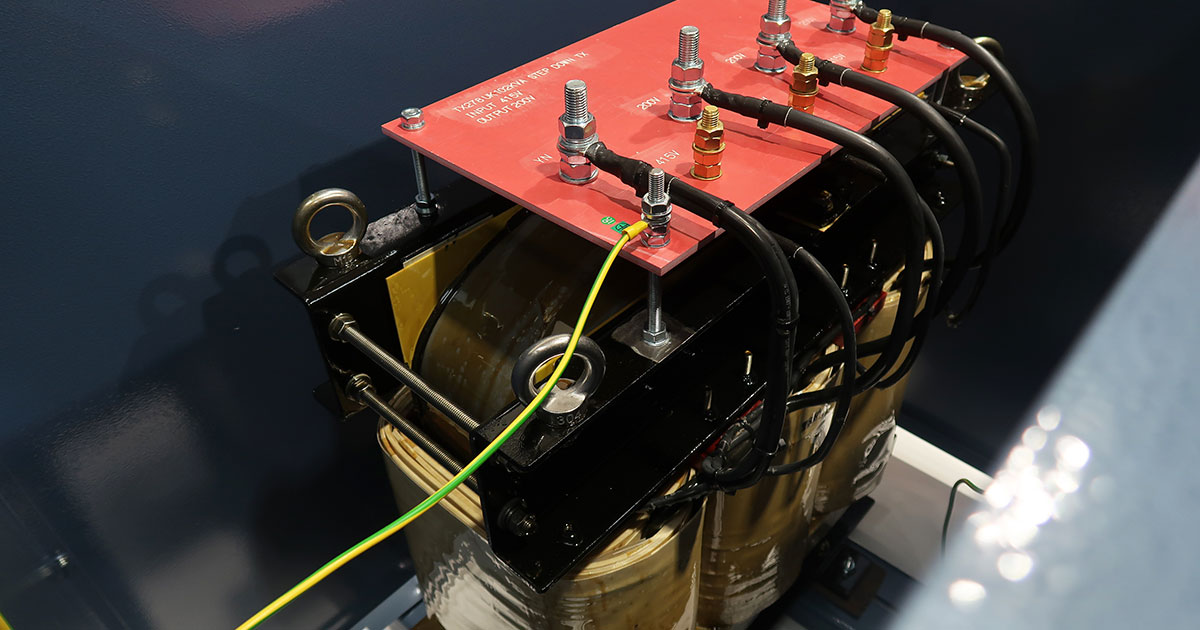

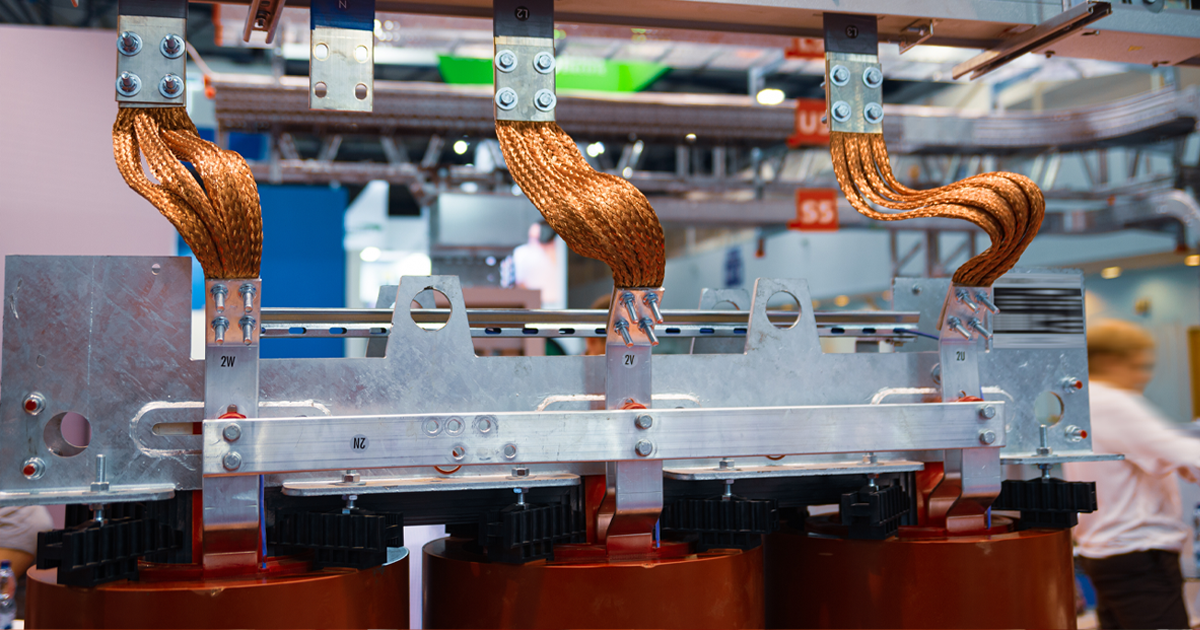

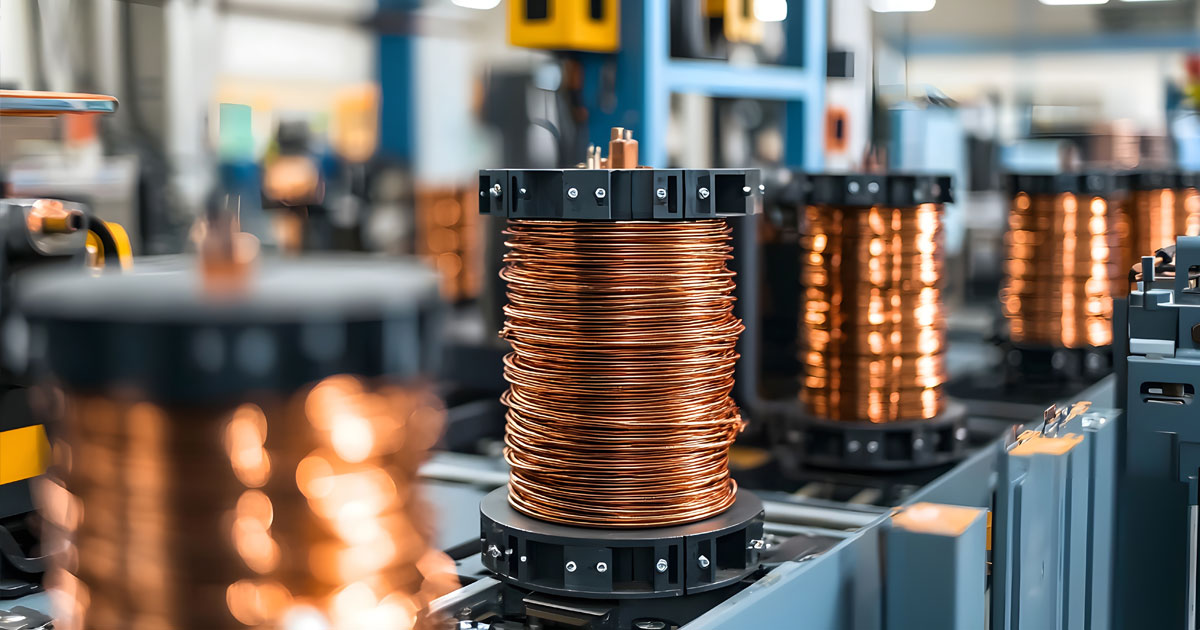

Voltage Optimisation

A Sheffield based company founded in 1932, Swann-Morton have become global market leaders and an industry pioneer.

The Swann-Morton Group were keen to minimise the environmental impact of its business operations and proactively seek to reduce their carbon emissions through their Environmental Management System.

Like many manufacturers, they are also facing increasing energy costs and a growing risk of power disruption.

Challenge

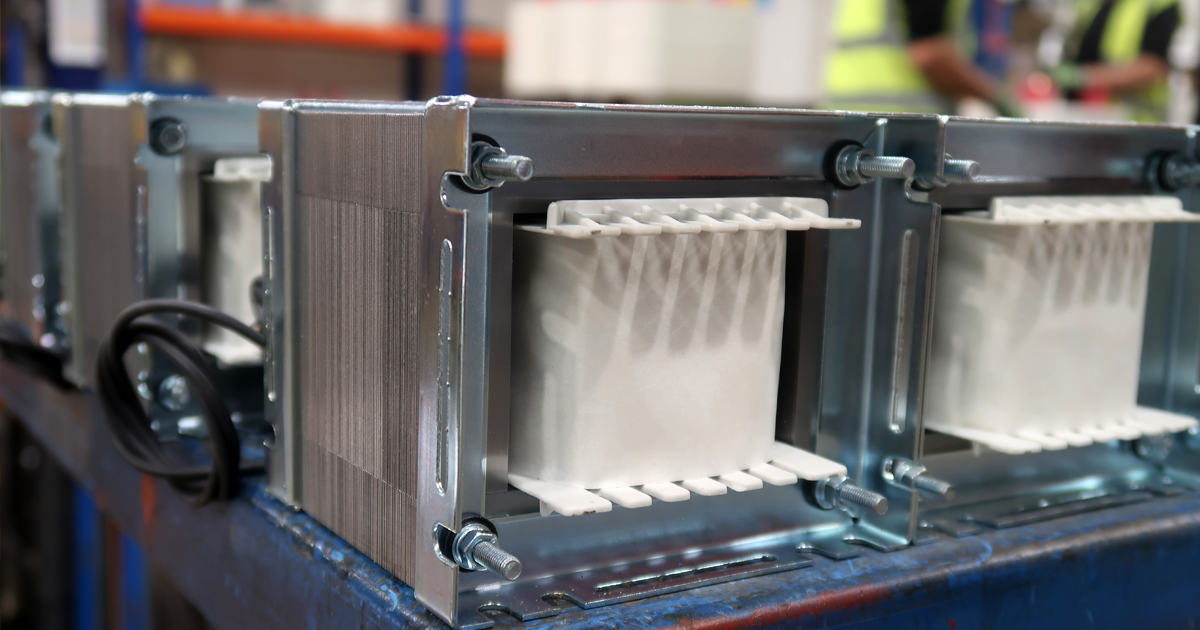

The challenge facing Swann Morton was to implement a proven and reliable technology that was able to effectively reduce on-site energy consumption without affecting any of the operations and manufacturing processes.

Approaching fellow Made in Sheffield accredited company Powerstar, Swann-Morton requested a site survey to provide them with a comprehensive overview of their energy usage. This allowed opportunities to reduce consumption, improve sustainability and bolster resilience to be effectively identified.

Solution

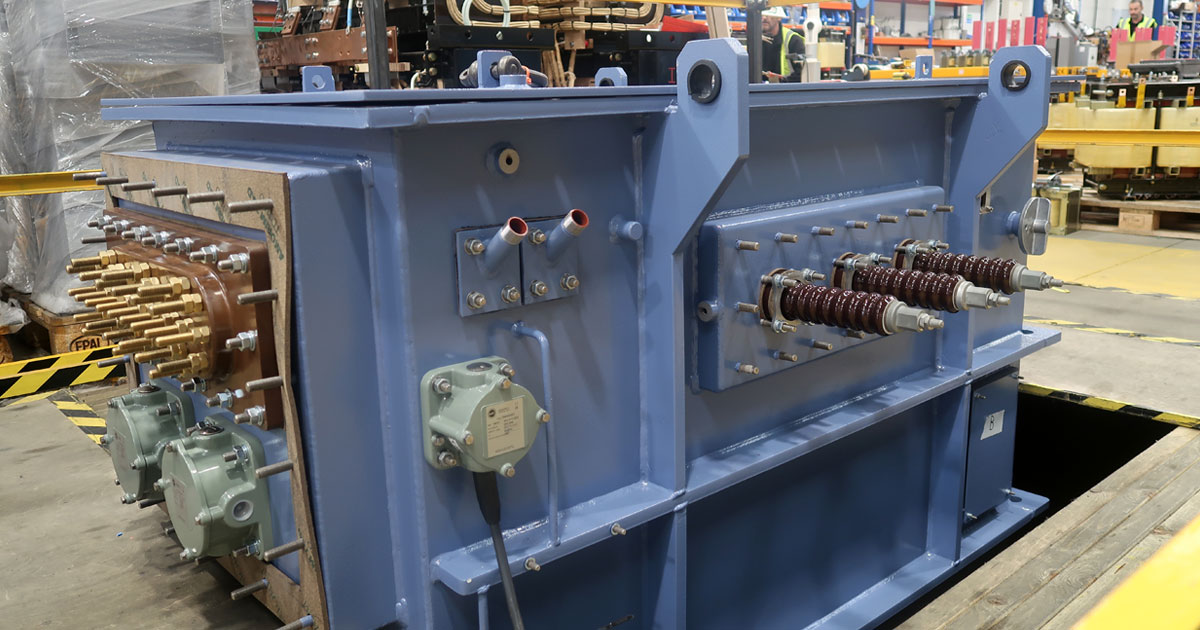

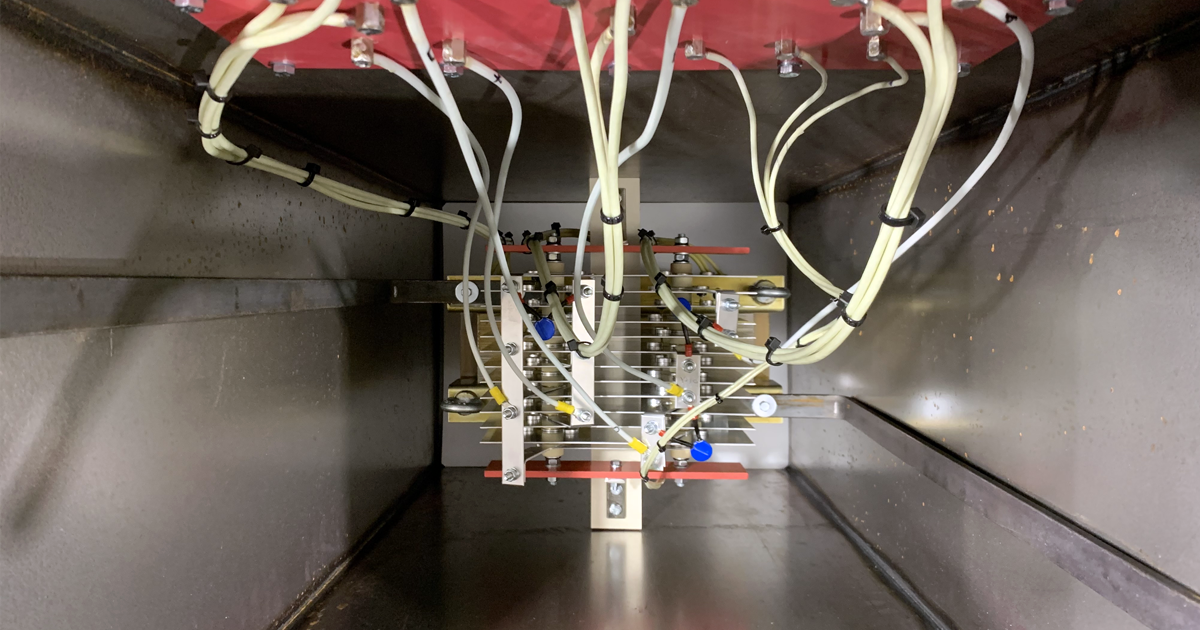

A dedicated project engineer was assigned to the customer, ensuring that a system was installed that met all of their specifications. This engineer was also responsible for ensuring that installation was carried out without any disruption to Swann-Morton’s business operations and without compromising their energy resilience.

Along with facilitating the installation, the dedicated project engineer acted as the main contact for the client and managed the process throughout, dealing with any problems, concerns and questions from Swann Morton throughout.

Result

Voltage optimisation solutions installed by Powerstar have reduced Swann Morton’s annual electricity consumption by 10%. This not only results in an annual saving of over £11,500, but also reduces the annual carbon emissions of the site by 102 tonnes. More stable energy supply also ensures that their precision manufacturing process is not impacted by a fluctuating voltage supply.